Power TransformersCurrent location :Home > Power Transformers

- Time:2024-3-22 17:24:55 Posted:E&C Technologies(Shenzhen) Co., Ltd.

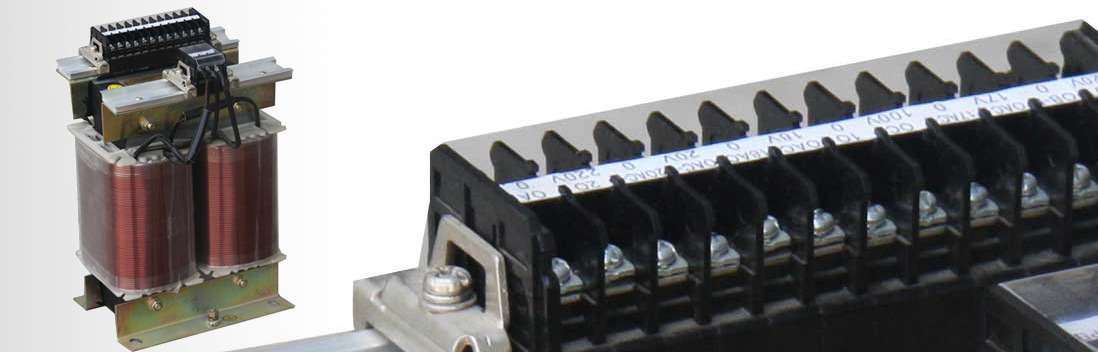

Power transformers transfer energy from a source to a load while changing the characteristics of the energy to meet specific requirements.

From industrial to household applications, power transformers make the equipment in our daily lives function efficiently.

Product Summary

ELANTAS ZHUHAI resins are perfect for keeping your power supply transformers in top performance condition day after day.

Epoxy resins and polyester resins offer a long field service history in power transformers. The resins provide outstanding moisture and chemical resistance in power transformers.

Solutions For

- UL Recognition

- Extended Service Life

- Vibration and Noise Reduction

- High Temperature Stress

Product Characteristics at a Glance

Product Base Resin Unique Characteristics Viscosity @25°C,mPa·s Cure Schedule Thermal Class PED 50S-35F HV UNSATURATED POLYESTER Single component, low viscosity, filled to improve heat dissipa-tion ,offers thermal classes from 130°C to 220°C .The resin is specially designed resin for the impregnation of high voltage transformers . Available in black version. 750-1000 1-3 hours @150-170°C 220°C PED 50S PRE-CAT POLYESTER UNSATURATED POLYESTER Low viscosity coupled with fast cure times for ultimate impregna-tion coupled with good cured resiliency to reduce noise in motor operation. 90-130 2-6 hours @150-170°C 200°C PED 70VT PRE-CAT UNSATURATED POLYESTER Single component, pre-catalysed resin used for the impregnation transformer coils. PED70VT has excellent tank stability and can be used in high voltage systems. 295-425 2-6 hours @130-150°C 200°C R2003S PRE-CAT UNSATURATED POLYESTER Single component. It exhibits good tank stability coupled with good bond strength, low shrinkage and chemical / moisture re-sistance. Available in black version and meet UL94-V0 flame retardant products. 350-650 2-4 hours @150°C 180°C 5183SW POLYESTER RESIN UNSATURATED POLYESTER Two-component system,Chemically promoted for low temperature cure,Low viscosity,Semi-flexible for vibration and noise sup-pression,UL recognized insulation systems up to class 240,UV light fluorescent 80-150 cps 30-60 minutes @120°C 180°C Elan-protect ®UP142 UNSATURATED POLYES-TERIMIDE Single component, VOC-free, low emissions, thermal class (180H),good penetration, good resin retention, low electro-discharge while frequency changes, excellent heat resistance. 900-1500 2hours@150°C

1hour@160°C180°C E468-2FC SOLVENTLESS EPOXY RESIN An unfilled, low viscosity, heat curing electrical insulation resin. It is a high dielectric compound that reduces core noise and wire vibration. 290-400 2-4 hours @135°C 200°C E478 THIXO VPI RESIN EPOXY RESIN Single component, low viscosity, high thixotropic, low emission. 1500-3000 3 hours @150°C 180°C

Power Transformers

Related Products